2022 High quality Fep Resin - FEP Dispersion (DS603A/C) for coating and impregnation – Huaxia Shenzhou

2022 High quality Fep Resin - FEP Dispersion (DS603A/C) for coating and impregnation – Huaxia Shenzhou Detail:

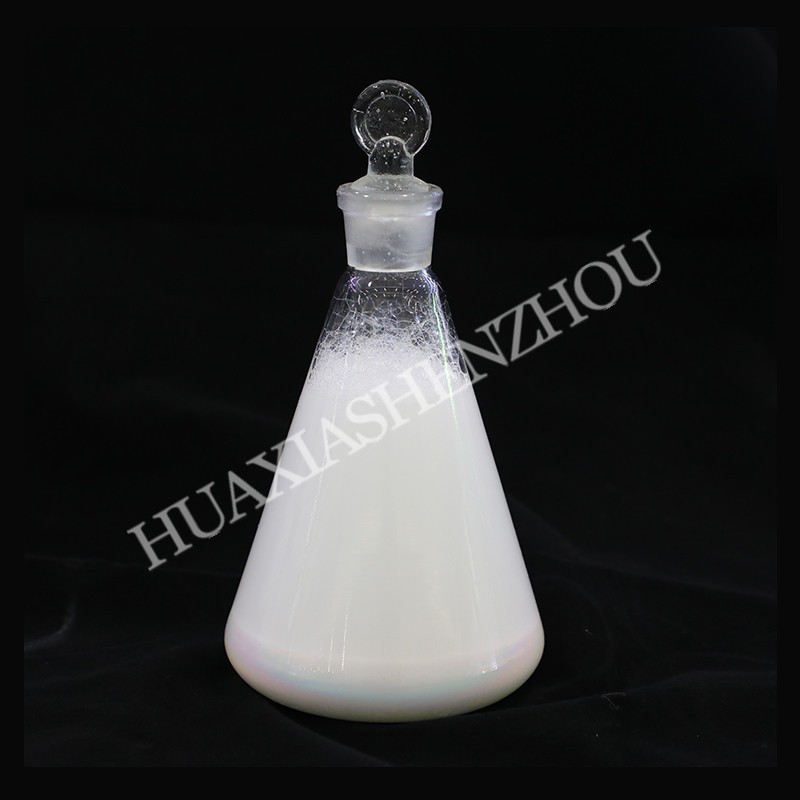

FEP Dispersion DS603 is the copolymer of TFE and HFP, stablized with non-ionic surfactant. It endow FEP products which can’t be processed by traditional methods several unique properties.The resin in emulsion is real thermoplastic plastic with typical outstanding characteristics of fluoride Resin: It can be used at temperature up to 200℃ continuously, the maximum operating temperature is 240℃. It is intert to almost all industrial chemicals and solvents. Its products have excellent thermal stability, corrosion resistance,excellent chemical intertness,good electrical insulation, and low coefficient of friction.

Conformable with Q/0321DYS 004

Technical Indexs

| Item | Unit | DS603 | Test Method/Standards | |

| Appearance | / | A | C | |

| Melting Index | g/10min | 0.8-10.0 | 3.0-8.0 | GB/T3682 |

| Solid | % | 50.0±2.0 | / | |

| Surfactant concentration | % | 6.0±2.0 | / | |

| PH Value | / | 8.0±1.0 | 9.0±1.0 | GB/T9724 |

Application

It can used for coating,impregnation.It is also suitable for the processing of many products, including heat resistant PTFE impregnated fiber surface coating, PWB, or electrical insulation materials,injection film, or chemical isolation materials, as well as PTFE/FEP mutual connection melt adhesive. The liquid also can be used for modulation of the underlying substrate metal coating, and for the production of glass cloth composite antifouling coating,and polyimide composite as high insulation membrane.Thereinto, DS603C is mainly used for the coating of single-side film.

Attention

1.The processing temperature should not exceed 400℃ to prevent toxic gas from releasing .

2.Stiring the stored product two or there tines a month to avoid any possible precipitation.

Package, Transportation and Storage

1.Packed in plastic drums. Net weight is 25kg per drum.

2.Stored in clean and dry places.Temperature range is 5℃~30℃.

3.The product is transported according to non-dangerous product, avoid heat, moisture or strong shock.

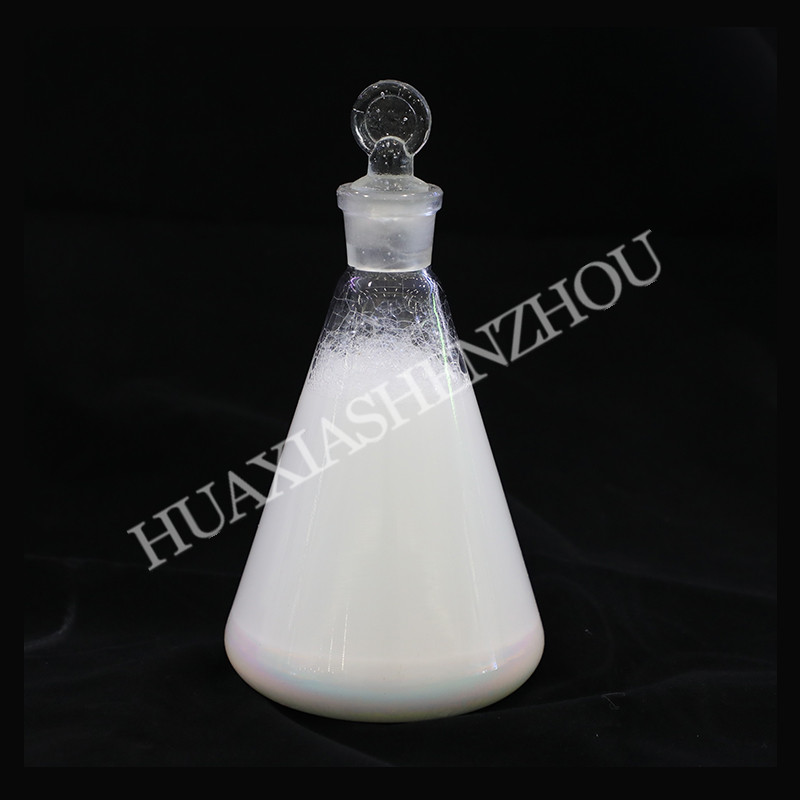

Product detail pictures:

Related Product Guide:

Sticking to your belief of "Creating solutions of high quality and generating buddies with people from all around the world", we always put the fascination of customers to start with for 2022 High quality Fep Resin - FEP Dispersion (DS603A/C) for coating and impregnation – Huaxia Shenzhou , The product will supply to all over the world, such as: Qatar, Leicester, Barcelona, After years of development, we have formed strong ability in new product development and strict quality control system to ensure excellent quality and service. With the support of many long term cooperated customers, our products are welcomed all over the world.

The quality of the products is very good, especially in the details, can be seen that the company work actively to satisfy customer's interest, a nice supplier.