Excellent quality Raw Materisl Of Solar Backplane Film - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou

Excellent quality Raw Materisl Of Solar Backplane Film - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou Detail:

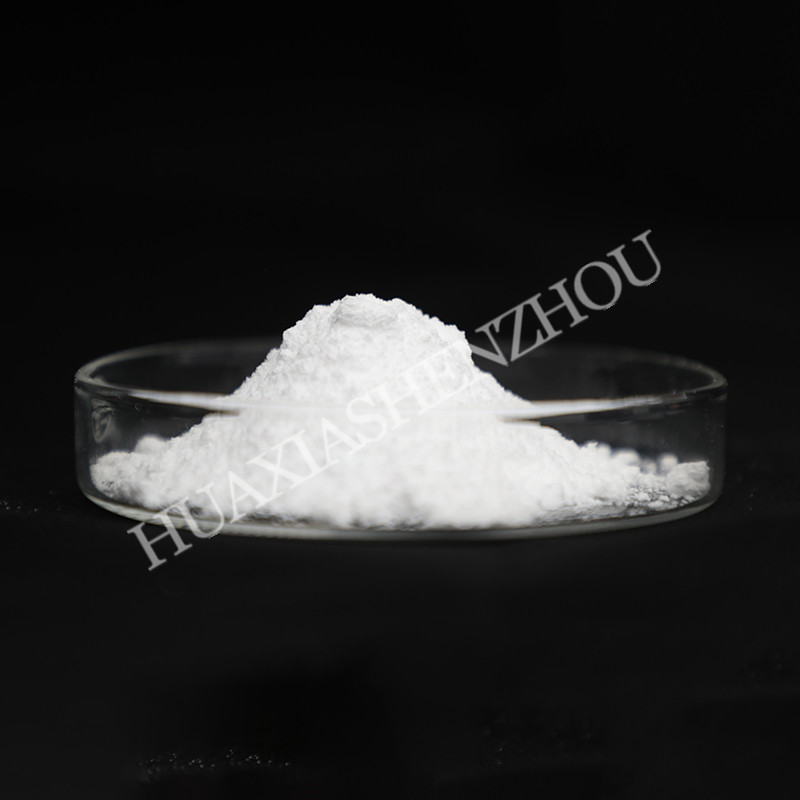

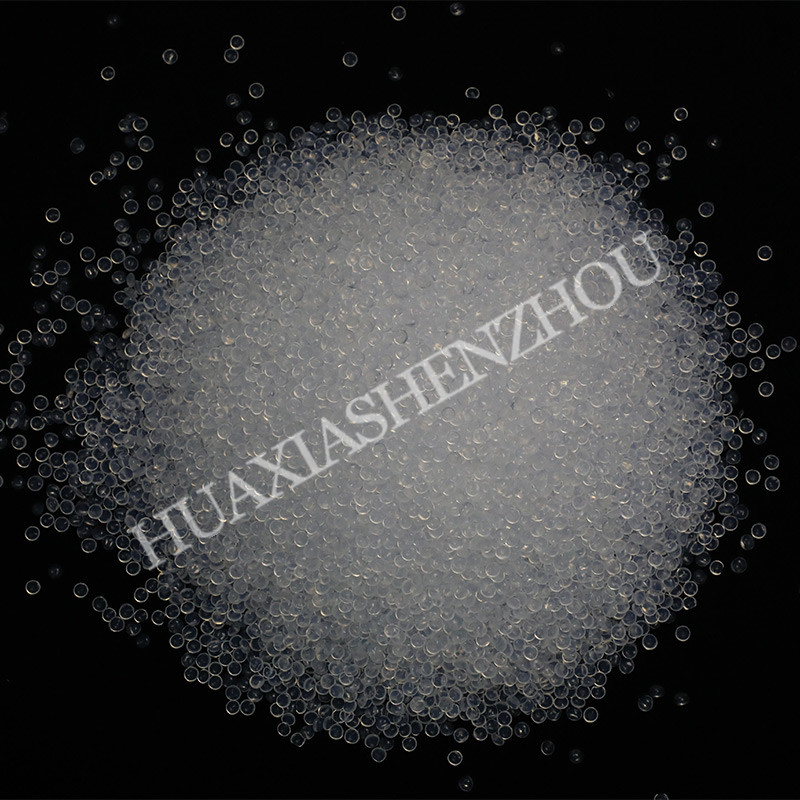

PVDF DS206 is the homopolymer of vinylidene fluoride, which has low melting viscosity. DS206 is one kind of thermoplastic fluoropolymers.It has fine mechanical strength and toughness, fine chemistry corrosion resistance and is suitable to produce PVDF products by injection, extrusion and other processing technologies. It is a versatile engineering plastic with excellent physical and chemical properties, making it widely used in high performance products, appearance milky white columnar particles.

Conformable with Q/0321DYS014

Technical Indexs

| Item | Unit | DS206 | Test Method/Standards | |||||

| DS2061 | DS2062 | DS2063 | DS2064 | |||||

| Appearance | / | Pellet/Powder | / | |||||

| Melting Index | g/10min | 1.0-7.0 | 7.1-14.0 | 14.1-25.0 | ≥25.1 | GB/T3682 | ||

| Tensile Strength,≥ | MPa | 35.0 | GB/T1040 | |||||

| Elongation at break,≥ | % | 25.0 | GB/T1040 | |||||

| Standard relative density | / | 1.77-1.79 | GB/T1033 | |||||

| Melting Point | ℃ | 165-175 | GB/T28724 | |||||

| Thermal Decomposition,≥ | ℃ | 380 | GB/T33047 | |||||

| Hardness | Shore D | 70-80 | GB/T2411 | |||||

Application

DS206 is suitable for producing PVDF products by injection molding,extrusion and other processing technology. Melt strength of high molecular weight PVDF(low Melting Index) is good, can get thin film, sheet, pipe, bar by extrusion; low molecular weight PVDF(high and medium Melting Index), can be processed by injection molding.

Attention

Keep this product from high temperature to prevent toxic gas releasing at the temperature above 350℃.

Package, Transportation and Storage

1.Packed in antistatic bag,1MT/bag.Powder packed in plastic drums,and circular barrels outside,40kg/drum.Packed in antistatic bag,500kg/bag.

2.Stored in clearn and dry places,Within 5-30℃ temperature range.Avoid contamination from dust and moisture.

3.The product should be transported as non-dangerous product,avoid heat,moisture and strong shock.

Product detail pictures:

Related Product Guide:

We are also focusing on improving the stuff management and QC system so that we could keep great advantage in the fiercely-competitive business for Excellent quality Raw Materisl Of Solar Backplane Film - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou , The product will supply to all over the world, such as: Paraguay, panama, Florence, Providing Quality Products, Excellent Service, Competitive Prices and Prompt Delivery. Our products are selling well both in domestic and foreign markets. Our company is trying to be one important suppliers in China.

This is the first business after our company establish, products and services are very satisfying, we have a good start, we hope to cooperate continuous in the future!