Hot New Products Fluoroethylenepropylene - FEP Resin (DS610) for wire insulation layer, tubes, film and automotive cable – Huaxia Shenzhou

Hot New Products Fluoroethylenepropylene - FEP Resin (DS610) for wire insulation layer, tubes, film and automotive cable – Huaxia Shenzhou Detail:

FEP DS610 Series are the melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene without additives that meets the requirements of ASTM D 2116. FEP DS610 Series have good thermal stability, outstanding chemical inertness, good electrical insulation, non-aging characteristics, exceptional dielectric properties, low flammability, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption and excellent weather resistance.

Conformable with Q/0321DYS003

Technical Indexs

| Item | Unit | 610A | 610B | Test Method/Standards |

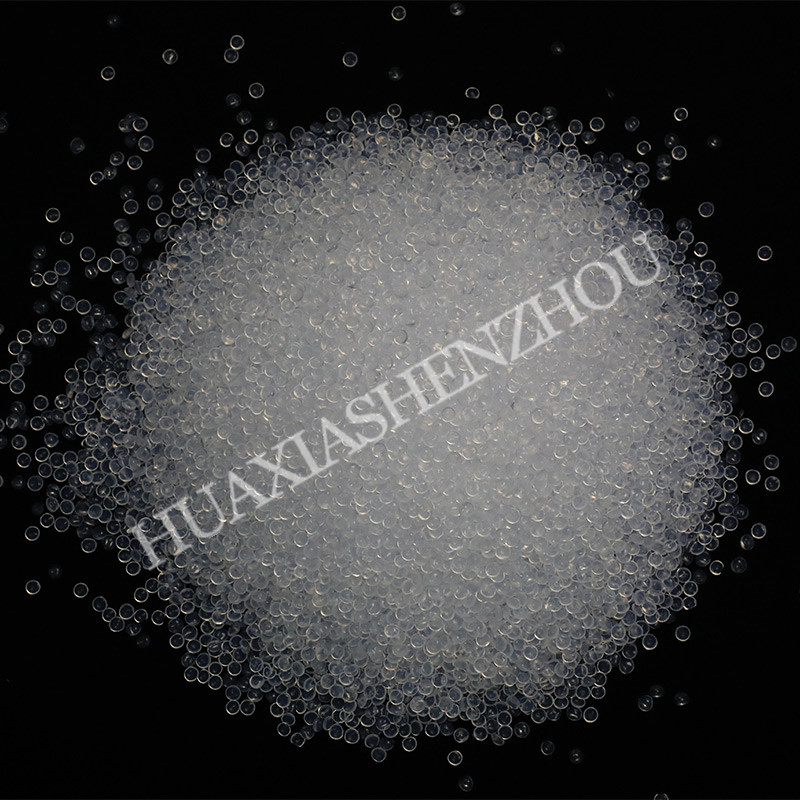

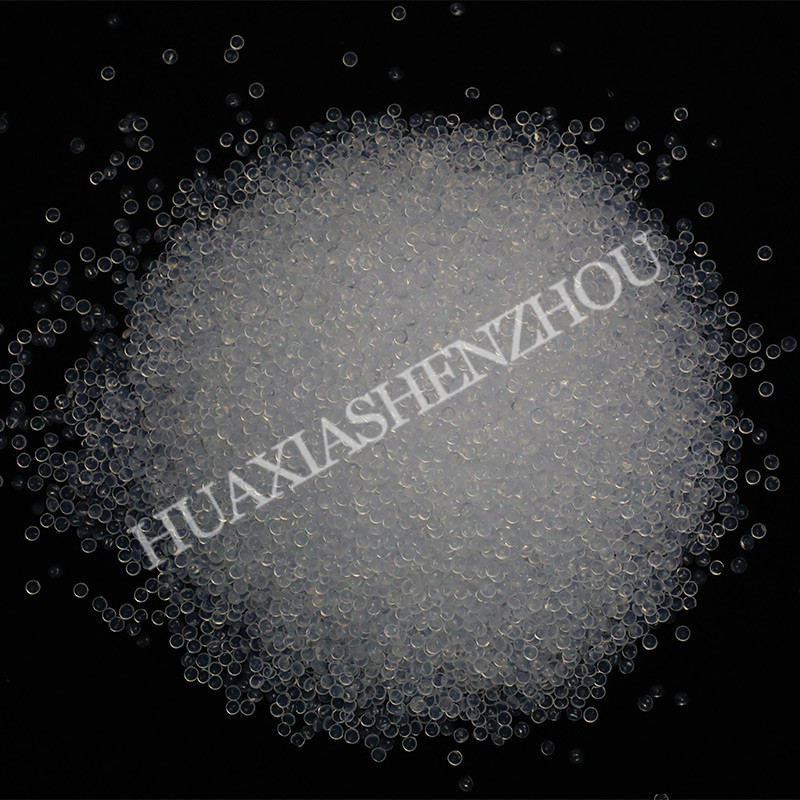

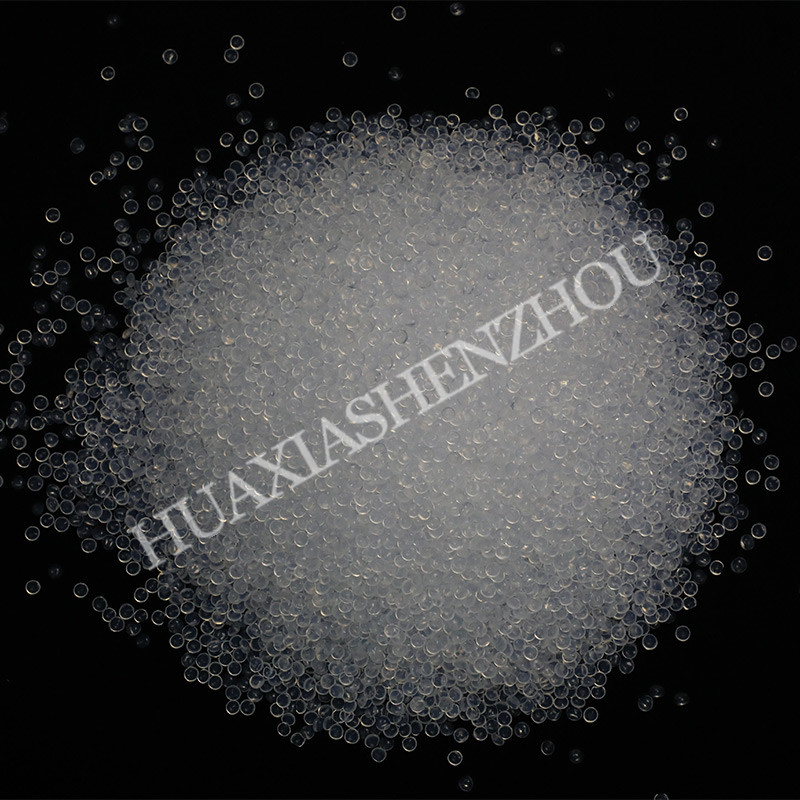

| Appearance | / | Translucent particle,with impurities such as metal debris and sand,containing visible black particles percentage point less than 1% | HG/T 2904 | |

| Melting Index | g/10min | 5.1-8.0 | 8.1-12.0 | ASTM D2116 |

| Tensile Strength,≥ | MPa | 22 | ASTM D638 | |

| Elongation at break,≥ | % | 310 | ASTM D638 | |

| Relative Gravity | / | 2.12-2.17 | ASTM 792 | |

| Melting Point | ℃ | 265±10 | ASTM D4591 | |

| Dielectric Constant(106Hz),≤ | / | 2.15 | ASTM D1531 | |

| Dissipation Factor(106Hz),≤ | / | 7.0×10-4 | ASTM D1531 | |

| Heat Stress Cracking Resistance | / | / | HG/T 2904 | |

| MIT≥ | cycles | / | ASTM/D2176 | |

Application

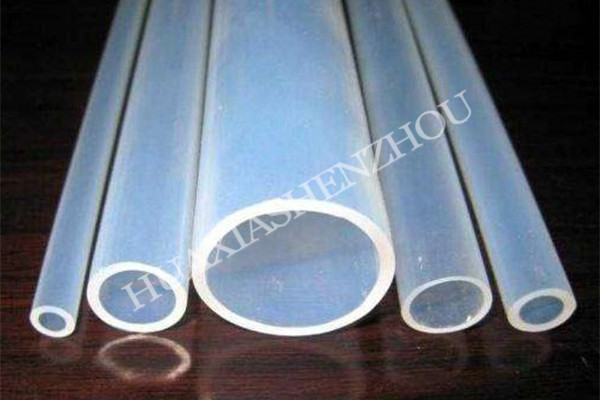

Extrusion processed for generic type resin, mainly used for wire insulation layer, tubes, film and automotive cable.

Attention

The processing temperature should not exceed 420℃, to prevent toxic gas from releasing.

Package, Transportation and Storage

1.Packed in plastic bag of 25kgs net each.

2.Stored in clean, cool and dry places,to avoid contamination from foreign substances such as dust and moisture.

3.Nontoxic, noninflammable, inexplosive, no corrosion, the product is transported according to non-dangerous product.

Product detail pictures:

Related Product Guide:

Assume full accountability to fulfill all demands of our purchasers; attain continual advancements by marketing the advancement of our clientele; grow to be the final permanent cooperative partner of purchasers and maximize the interests of purchasers for Hot New Products Fluoroethylenepropylene - FEP Resin (DS610) for wire insulation layer, tubes, film and automotive cable – Huaxia Shenzhou , The product will supply to all over the world, such as: Greek, Armenia, US, Till now, the items list has been updated regularly and attracted clients from around the globe. Comprehensive facts is often obtained in our web-site and you'll be served with premium quality consultant service by our after-sale group. They are likely to help you get thorough acknowledge about our goods and make a satisfied negotiation. Company go to to our factory in Brazil is also welcome at any time. Hope to obtain your inquiries for any pleased co-operation.

The company account manager has a wealth of industry knowledge and experience, he could provide appropriate program according our needs and speak English fluently.