Manufacturer for Supplier Of Sherwin Willams - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou

Manufacturer for Supplier Of Sherwin Willams - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou Detail:

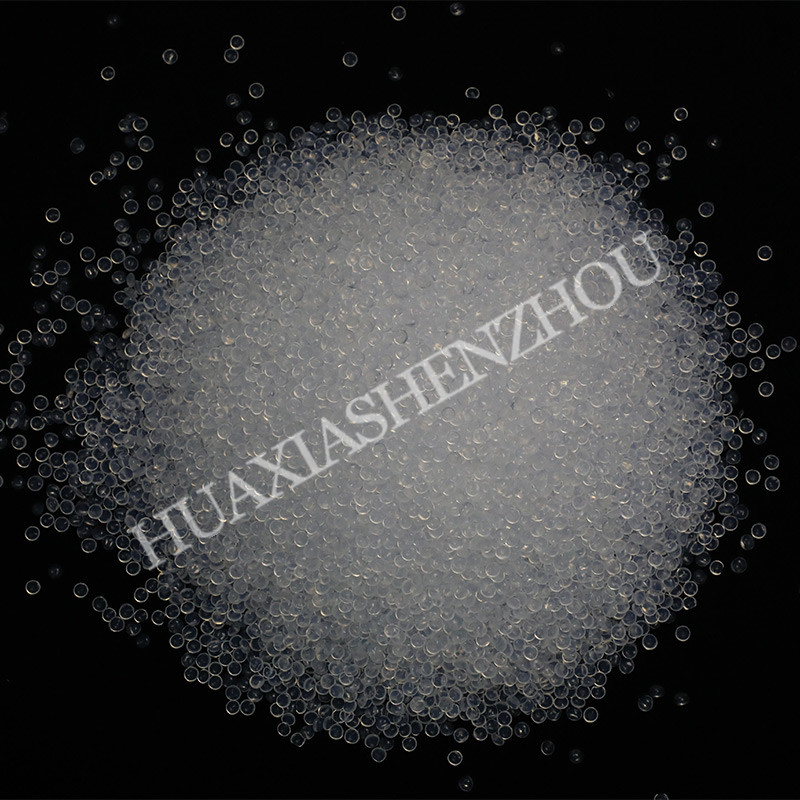

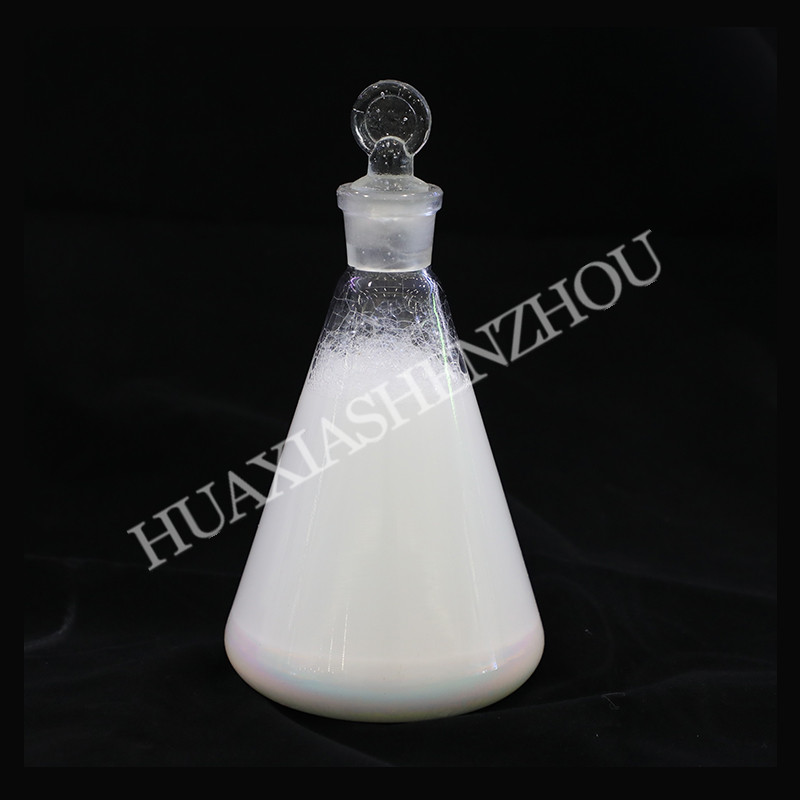

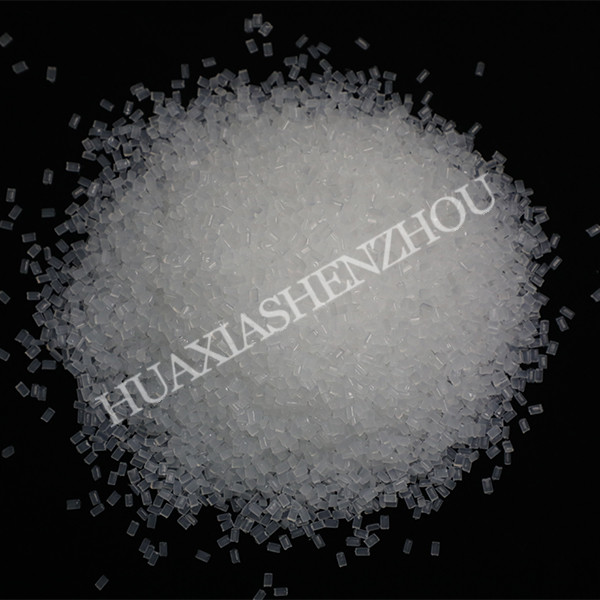

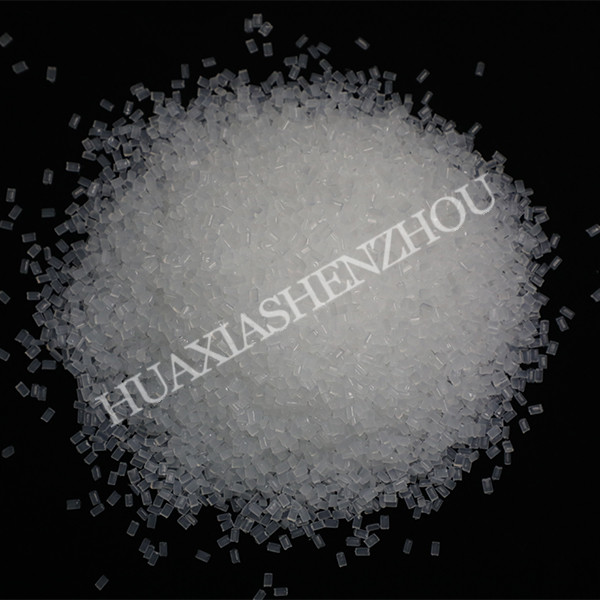

PVDF DS206 is the homopolymer of vinylidene fluoride, which has low melting viscosity. DS206 is one kind of thermoplastic fluoropolymers.It has fine mechanical strength and toughness, fine chemistry corrosion resistance and is suitable to produce PVDF products by injection, extrusion and other processing technologies. It is a versatile engineering plastic with excellent physical and chemical properties, making it widely used in high performance products, appearance milky white columnar particles.

Conformable with Q/0321DYS014

Technical Indexs

| Item | Unit | DS206 | Test Method/Standards | |||||

| DS2061 | DS2062 | DS2063 | DS2064 | |||||

| Appearance | / | Pellet/Powder | / | |||||

| Melting Index | g/10min | 1.0-7.0 | 7.1-14.0 | 14.1-25.0 | ≥25.1 | GB/T3682 | ||

| Tensile Strength,≥ | MPa | 35.0 | GB/T1040 | |||||

| Elongation at break,≥ | % | 25.0 | GB/T1040 | |||||

| Standard relative density | / | 1.77-1.79 | GB/T1033 | |||||

| Melting Point | ℃ | 165-175 | GB/T28724 | |||||

| Thermal Decomposition,≥ | ℃ | 380 | GB/T33047 | |||||

| Hardness | Shore D | 70-80 | GB/T2411 | |||||

Application

DS206 is suitable for producing PVDF products by injection molding,extrusion and other processing technology. Melt strength of high molecular weight PVDF(low Melting Index) is good, can get thin film, sheet, pipe, bar by extrusion; low molecular weight PVDF(high and medium Melting Index), can be processed by injection molding.

Attention

Keep this product from high temperature to prevent toxic gas releasing at the temperature above 350℃.

Package, Transportation and Storage

1.Packed in antistatic bag,1MT/bag.Powder packed in plastic drums,and circular barrels outside,40kg/drum.Packed in antistatic bag,500kg/bag.

2.Stored in clearn and dry places,Within 5-30℃ temperature range.Avoid contamination from dust and moisture.

3.The product should be transported as non-dangerous product,avoid heat,moisture and strong shock.

Product detail pictures:

Related Product Guide:

Our company sticks to the principle of "Quality is the life of the company, and reputation is the soul of it" for Manufacturer for Supplier Of Sherwin Willams - PVDF Resin For injection and extrusion (DS206) – Huaxia Shenzhou , The product will supply to all over the world, such as: Macedonia, Colombia, Toronto, Strict quality control is executed in each link of the whole production process.We sincerely hope to establish the friendly and mutual-beneficial cooperation with you. Based on high quality products and perfect pre-sales /after-sales service is our idea, some clients had cooperated with us for more than 5 years.

It is not easy to find such a professional and responsible provider in today's time. Hope that we can maintain long-term cooperation.