Massive Selection for Teflon Fep 9898 - FEP Resin (DS610H&618H) – Huaxia Shenzhou

Massive Selection for Teflon Fep 9898 - FEP Resin (DS610H&618H) – Huaxia Shenzhou Detail:

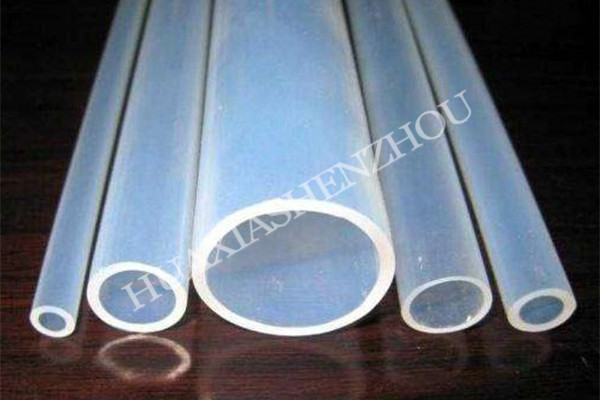

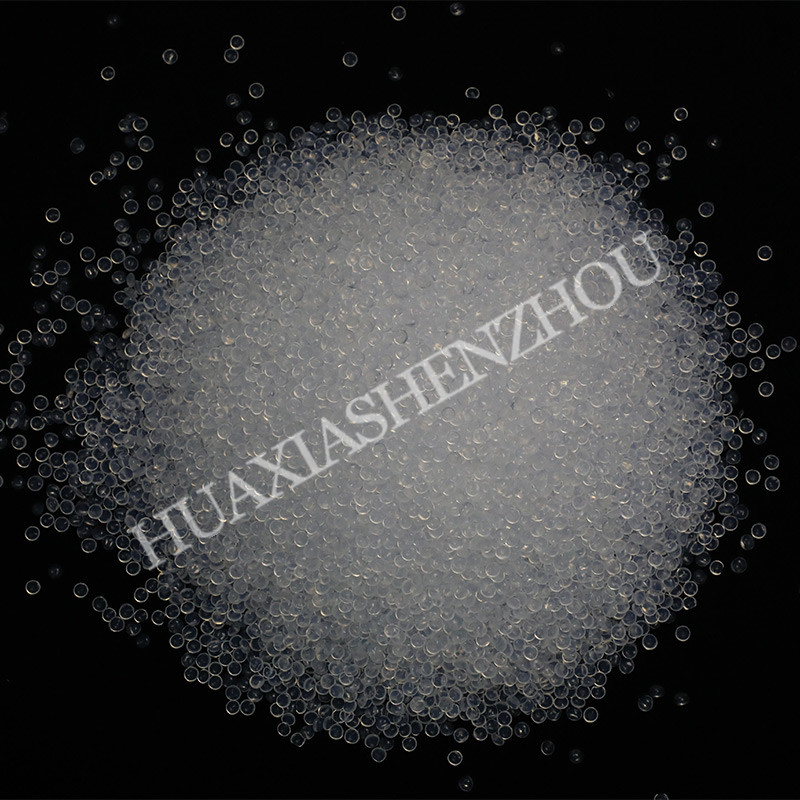

FEP DS618 series is a melt-processible copolymer of tetrafluoroethylene and hexafluoropropylene without additives that meets the requirements of ASTM D 2116. FEP DS618 series has good thermal stability, outstanding chemical inertness, good electrical insulation, non-aging characteristics, exceptional dielectric properties, low flammability, heat resistance, toughness and flexibility, low coefficient of friction, non-stick characteristics, negligible moisture absorption, and excellent weather resistance.DS618 series has high molecular weight resins of low melt index, with low extrusion temperature, high extrusion speed which is 5-8 times of ordinary FEP resin.It is soft, anti-burst, and has good toughness.

Conformable with Q/0321DYS 003

Technical Indexs

| Item | Unit | 610H | DS618H | Test Method/Standards |

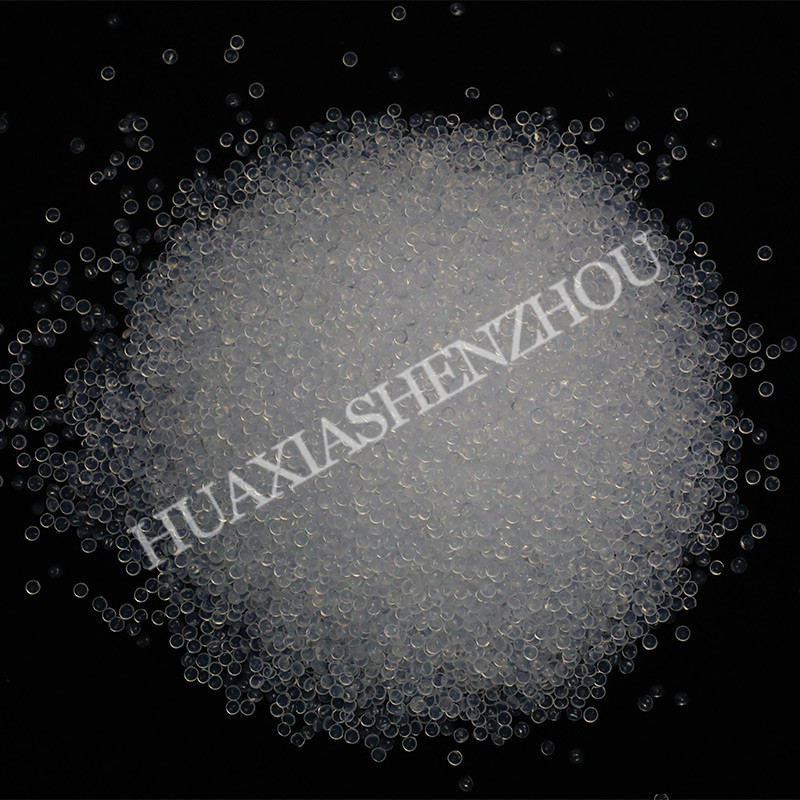

| Appearance | / | Translucent particle,with impurities such as metal debris and sand,containing visible black particles percentage point less than 1% | HG/T 2904 | |

| Melting Index | g/10min | 5.1-12.0 | 24-42 | GB/T 3682 |

| Tensile Strength,≥ | MPa | 25 | 21 | GB/T 1040 |

| Elongation at break,≥ | % | 330 | 320 | GB/T 1040 |

| Relative Gravity | / | 2.12-2.17 | GB/T 1033 | |

| Melting Point | ℃ | 265±10 | GB/T 28724 | |

| Dielectric Constant(106HZ),≤ | / | 2.07 | GB/T 1409 | |

| Dielectric Factor(106HZ),≤ | / | 5.7×10-4 | GB/T 1409 | |

| MIT≥ | cycles | 30000 | / | ASTM/D2176 |

| Item | Unit | 610H | DS618H | Test Method/Standards |

Application

Mainly in the aviation and aerospace industries, the MTR transport vehicles, automatic switching equipment, well test equipment, flame alarm systems, high-rise building, fire regional wires, cables, computers, communication networks, electrical fields, particularly applicable for high-speed extrusion small-caliber wire insulation material.It is more economical when used in where no high stress cracking resistance is required.

Attention

The processing temperature should not exceed 420℃, to prevent toxic gas from releasing.

Package, Transportation and Storage

1.Packed in plastic bag of 25kgs net each.

2.Stored in clean, cool and dry places,to avoid contamination from foreign substances such as dust and moisture.

3.Nontoxic, noninflammable, inexplosive, no corrosion, the product is transported according to non-dangerous product.

Product detail pictures:

Related Product Guide:

We're commitment to offer you the aggressive cost ,superb products and solutions top quality, too as fast delivery for Massive Selection for Teflon Fep 9898 - FEP Resin (DS610H&618H) – Huaxia Shenzhou , The product will supply to all over the world, such as: Luxemburg, Czech Republic, Cape Town, To work with an excellent products manufacturer, our company is your best choice. Warmly welcome you and opening up the boundaries of communication. We are the ideal partner of your business development and look forward to your sincere cooperation.

With a positive attitude of "regard the market, regard the custom, regard the science", the company works actively to do research and development. Hope we have a future business relationships and achieving mutual success.