New Fashion Design for Pvdf Extrusion Moulding - PVDF(DS2011)powder for coating – Huaxia Shenzhou

New Fashion Design for Pvdf Extrusion Moulding - PVDF(DS2011)powder for coating – Huaxia Shenzhou Detail:

PVDF Powder DS2011 is the homopolymer of vinylidene fluoride for coating.DS2011 have fine chemistry corrosion resistance,fine ultraviolet ray and high energy radiativity resistance.

Well-known fluorine carbon bonds is the basic condition can guarantee the fluorine carbon coating weatherability since fluorocarbon bond is one of the strongest bonds in nature, the higher the fluorine content of fluorine carbon coating, weather resistance and durability of the coating is better. DS2011 fluorine carbon coating shows excellent outdoor weather resistance and excellent aging resistance, DS2011 fluorine carbon coating can protect against the rain, moisture, high temperature, ultraviolet light, oxygen, air pollutants, climate change, to achieve the purpose of long-term protection.

It is typically a semi-crystalline polymer that is approx. 50% amorphous. It has highly regular structure with most of VDF units joined head-to-tail with very less percentage of monomer units joined head-to-head.

Conformable with Q/0321DYS014

Technical Indexs

| Item | Unit | DS2011 | Test Method/Standards |

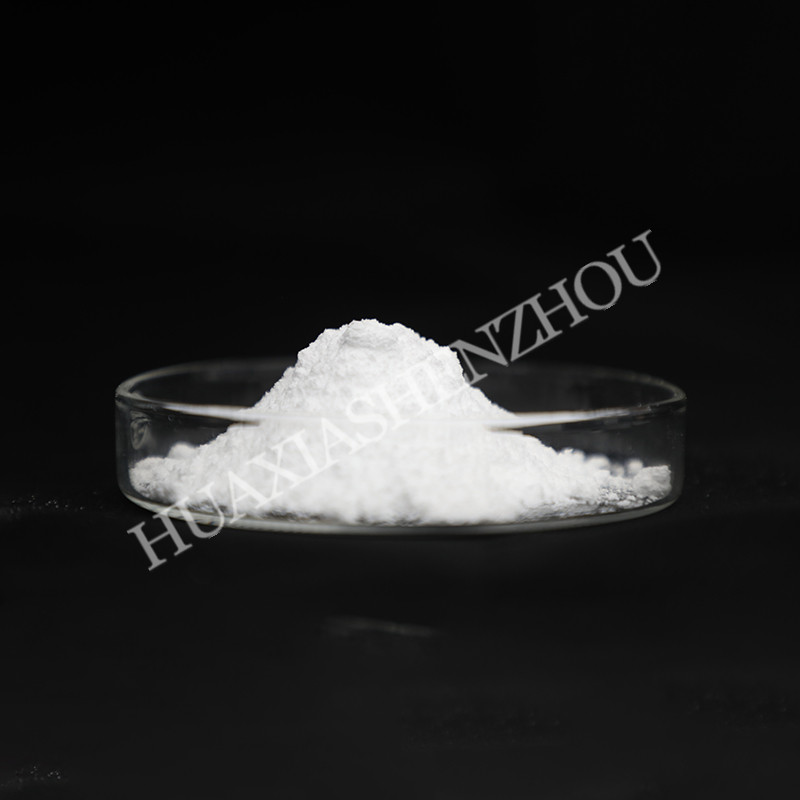

| Appearance | / | White powder | / |

| Odor | / | Without | / |

| Scattered Fineness,≤ | μm | 25 | GB/T6753.1-2007 |

| Melting Index | g/10min | 0.5-2.0 | GB/T3682 |

| Relative Density | / | 1.75-1.77 | GB/T1033 |

Application

The resin is used to produce fluorocarbon coating,PVDF coatings have the best UV resistance of any polymer used in coatings today. The carbon-fluorine bond is one of the strongest chemical bonds known. The bond gives PVDF resin-based coatings their stubborn resistance to chalking and erosion, as well as to harsh industrial and atmospheric pollutants.

Attention

Keep this product from high temperature to prevent toxic gas releasing at the temperature above 350℃.

Package, Transportation and Storage

1.Packed in antistatic bag,250kg/bag.

2.Stored in clean and dry places,and temperature range is 5-30℃.Avoid contamination from dust and moisture.

3.The product should be transported as non-dangerous product,avoiding heat,moisture and strong shock.

Product detail pictures:

Related Product Guide:

Fast and very good quotations, informed advisers to help you choose the correct merchandise that suits all your preferences, a short creation time, responsible excellent command and different companies for paying and shipping affairs for New Fashion Design for Pvdf Extrusion Moulding - PVDF(DS2011)powder for coating – Huaxia Shenzhou , The product will supply to all over the world, such as: Liberia, Panama, Austria, We have top engineers in these industries and an efficient team in the research. What is more, we have our own archives mouths and markets in China at low cost. Therefore, we can meet different inquiries from different clients. Please find our website to check more information from our products.

As a veteran of this industry, we can say that the company can be a leader in the industry, select them is right.